| Technical | Analysis of common injection molding defects and solutions | |

|

发布时间:2019/5/28 17:07:50 点击次数:1370

Technical | Analysis of common injection molding defects and solutions

To do plastic, you need to supplement some knowledge of plastic molds, and now Xiaobian shares with you the analysis and countermeasures of the causes of plastic injection molding defects

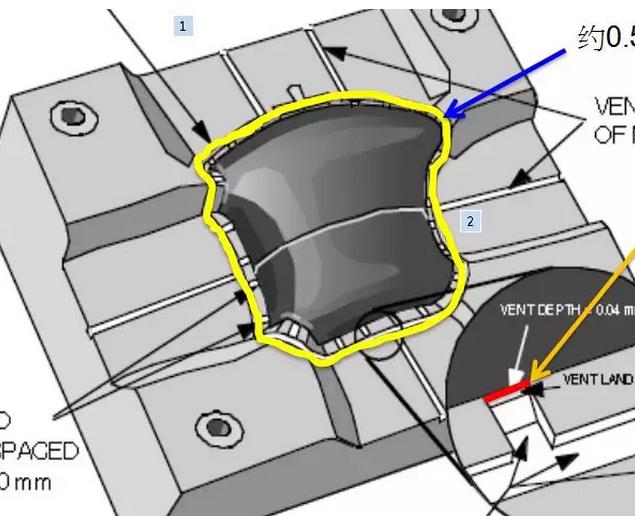

一、Burr problems

Undesirable phenomenon: When we see that there is a flying edge on the edge of the figure below, do not rush to conclusions;

二、Stress marks

Stress marks are due to the presence of obvious changes in thickness in the original design of the assembly, resulting in deformed stress trace defects in the finished plastic parts. Usually the stress marks will be more obvious on the back of the finished plastic part.

三、Dents/sink marks

Undesirable phenomenon: Dents refer to the depressions formed on the local surface of the plastic parts in places where the plastic flesh is thick such as ribs, ribs, and inner insert areas. Thick areas of meat are not adequately compensated by plastic when cooled.

四、Weld wires

Undesirable phenomenon: The welding wire is produced by the fusion glue in the filling process, because the flow wavefront of more than two directions is brought together, and the weld line affects the appearance problem, which will lead to the strength of the structural parts when it is serious.

五、char

Undesirable phenomena: The following figure on the right has poor injection burn, which is caused by injection molding sleepy gas;

六、Flow marks

Undesirable phenomenon: Flow marks are defects in which the plastic part creates water waves on the surface near the gate. This defect usually occurs when the gate is set in the middle of the cavity

七、Short shots

Undesirable phenomenon: Short shot is due to the fact that after completing the production process, the melt glue still cannot completely fill the mold cavity, resulting in a defective appearance of the final plastic part. Short shots are most likely to occur in thin areas or at the end of the flow.

八、Gate print

Undesirable phenomenon: appears on the back of the submerged gate or horn gate, caused by a large shear rate at the inlet gate

Recommended reading:

|

|

|

|

中文CN

Service hotline:

137-7631-9563