。

Gu'an Mould Cleaning Machine Mould Waterway Cleaning Machine Condenser Cleaning Machine is suitable for: ●Injection molding machine ●Air conditioning pipeline ●Mold waterway ●Production workshop water circulation system Middle water pipeline cleaning.

Gu'an Mould Cleaning Machine Mould Waterway Cleaning Machine Condenser Cleaning Machine

Suitable for: Injection molding machine

●Air conditioning pipeline

●Mold waterway

●Production workshop water circulation system

Water line cleaning in application.

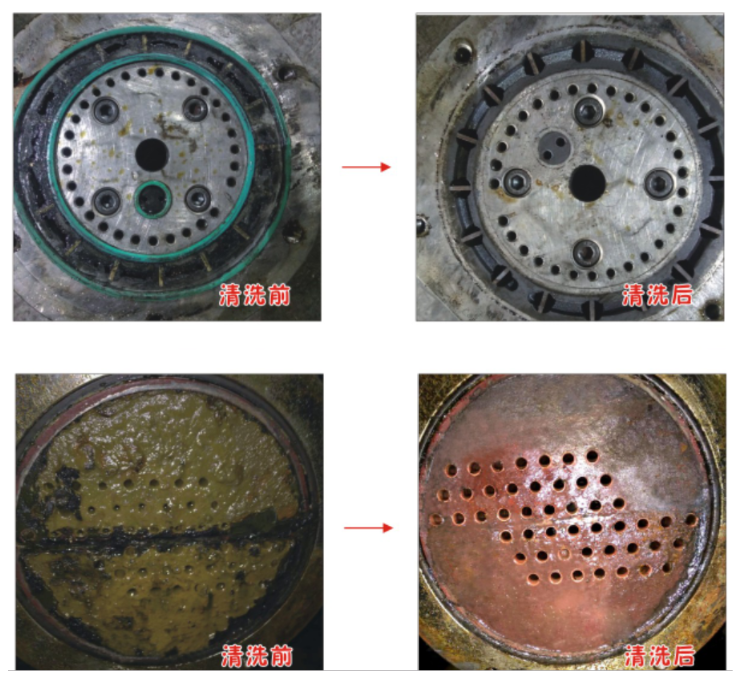

The necessity of regular cleaning of the circulating cooling water circuit:

●According to long-term research, when the thickness of the scale on the pipe wall reaches 0.05mm, the motor power will be increased by 20% to complete the original workload.

●Due to the generation of scale, the injection oil temperature is too high and the system pressure is unstable.

●The accumulation of scale and rust over the years leads to poor cooling effect of the mold waterway, prolonging the molding cycle, resulting in a decrease in output and quality, and an increase in cost.

●Solve the problem of production stoppage caused by poor water circulation system and reduce the cost of irregular maintenance.

Comparison of machine cleaning and labor costs (650T injection molding machine mold 20L barrel analysis)

Machine cleaning cost:

1. The total power of the equipment is 1.5KW/2, and the work can be completed in two hours. 2*1.5=3 degrees of electricity consumption*1 yuan = 3 yuan

2. 4 sets of molds can be cleaned by labor for 8 hours a day (1 person/150 yuan/day) 150÷4=37.5 yuan/set

3. The cost of a set of molds for cleaning agent is 50 yuan

4. The cost of cleaning a set of 650T injection molding machine molds is 3+37.5+50=90.5 yuan

Manual cleaning cost:

1. The 20L barrel of the 650T injection molding machine takes 2 people/2 days to clean.

2. RMB 150 per person/1 day, RMB 300 per person/day, RMB 30 for 2 days = RMB 600

3. Other auxiliary materials are 50 yuan for a set of molds.

4. The cost of cleaning a set of 650T injection molding machine molds is 600+50=650 yuan

solution

cleaning formula:

●Formula: Independent research and development of environmentally friendly waterway cleaning powder, the application of molecular peeling effect, the scale is removed through the water cycle, the independent formula ensures no corrosion effect, the cleaning formula has no effect on the mold material, sealing ring, plastic tube, copper tube, stainless steel, human body, etc. It can effectively loosen the scale and rust in the cooling waterway.

compressed air:

●Principle overview: By switching the forward and reverse directions of the water flow, the water and gas are integrated, and the extremely tiny bubbles are superimposed at the same point to generate a pressure of dozens of Mpa. The tiny air bubbles can penetrate the scale wall and rust wall, loosen them and wash them out. The attachment and corrosion on the blasting pipe wall are impacted, and the high-speed water flow takes away the cleaned dirt in the pipe

Post-use cost analysis report

1、Injection mold

Container (barrel) 20L new mold molding cycle is 23 seconds, after 6 months of use, the molding cycle is 24-25 seconds

Using Gu'an's mold cleaning machine, after 1 hour of cleaning, the mold forming cycle returns to 23 seconds, calculated according to 1 hour:

3600 seconds ÷ 23 seconds / mode = 157 modes

3600 seconds ÷ 24 seconds / mode = 150 modes 157 modes - 150 modes = 7 modes

3600 seconds ÷ 25 seconds / mode = 144 modes 157 modes - 144 modes = 13 modes

Calculated according to 20 hours a day: 20L barrel market price 18 yuan:

20 hours * 13 molds = 260 molds 260 molds * 18 yuan = 4680 yuan

20 hours * 7 molds = 140 molds 140 molds * 18 yuan = 2520 yuan

2、Injection molding machine cooler

The oil temperature of the 560T injection molding machine cooler before cleaning is 52 degrees. After cleaning, the oil temperature drops to 43 degrees. The normal operating temperature of hydraulic oil is 45 degrees. Long-term higher than 45 degrees will greatly damage the oil quality. If the temperature is too high, the machine lock will be reduced. The mold force also damages the hydraulic components of the machine, and the long-term high oil temperature also increases the maintenance rate of the injection molding machine.

The normal oil consumption of 650T injection molding machine is 8-9 barrels of oil, and each barrel of oil is 2800 yuan*8=22400

It is 22,400 yuan for each oil change once a year

Every year and a half to replace the oil is 22400 yuan ÷ 2 = 11200 yuan

Each oil change can save 11,200 yuan

Calculated with 10 machines: 11200 yuan * 10 sets = 112000 yuan

|

name |

Function |

Features |

other |

Features |

|

Double tank design |

Have |

When the waterway for cleaning the mold is finished, it can be cleaned with a second water tank filled with clean water for a few minutes, in order to clean the cleaning agent remaining in the waterway of the mold. |

none |

There is no double water tank design, so there must be cleaning agent left in the waterway. After a long time, I am worried that it will corrode the waterway. |

|

Cavitation + pulse + cleaning in forward and reverse directions |

Cavitation cleaning is a physical movement method. Two-way cleaning can speed up the cleaning speed and clean the rust and scale more thoroughly. |

Pulse + Electrolysis |

Electrolytic cleaning is a cleaning method that electrolyzes chemical cleaning agents. |

|

|

cleaning media |

detergent or water |

When the scale of the mold waterway is serious, it can be cleaned with 500 grams of cleaning agent and 100 kilograms of water. When the scale of the mold waterway is not very serious, only clean water can be used for cavitation peeling and cleaning. |

detergent |

Other mold waterway cleaning machines use pure cleaning agent to clean the mold waterway without adding clean water, and there is no double water tank design, which may cause serious corrosion to the interior of the mold waterway. |

|

Have |

The staff can come into contact with the cleaning agent to ensure the personal safety of the staff. |

unknown |

|

|

|

Emissions and volatile odors |

can be discharged directly |

Basically, there is no odor, and the workshop environment is guaranteed to be clean. |

It is unknown whether it can be directly discharged |

When cleaning with other cleaning agents, it will produce a more irritating odor. |

|

cleaning agent cost |

100 yuan/kg |

Use ratio: 500 grams to 100kg of clean water, can clean a set of large car molds, the cost is: 50 yuan can clean a set of molds. |

unknown |

|

|

total power |

1.5KW |

Relatively energy-saving compared to other companies' mold cleaners. |

Above 3.0kw |

|

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

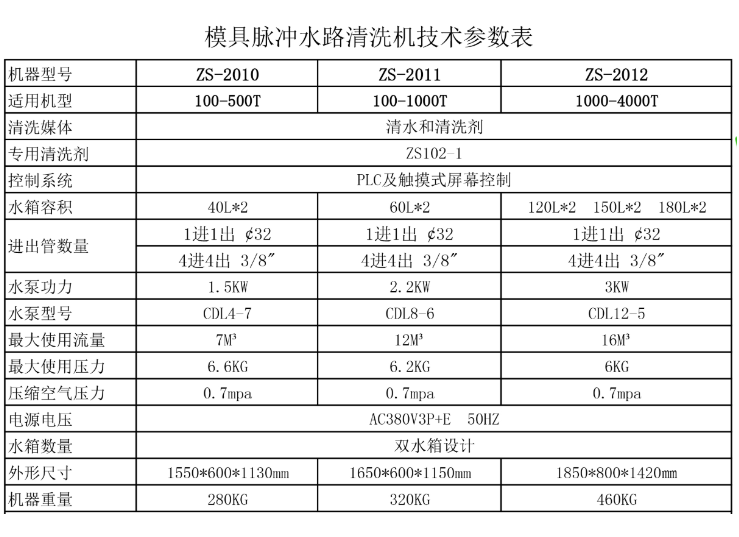

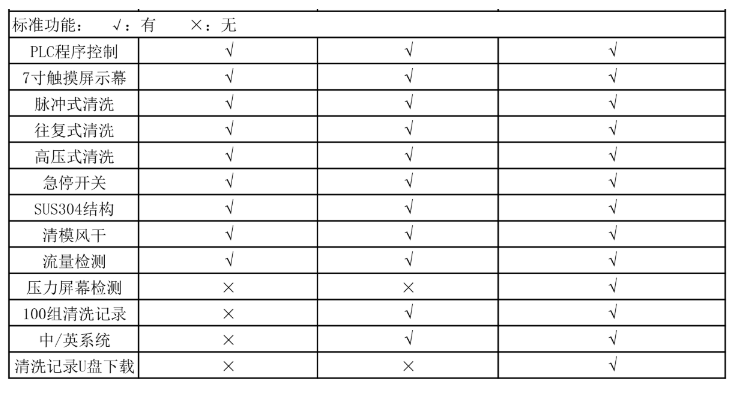

Product selection

technical support