Powerful Crusher | Powerful Crusher | Plastic Beater

一、Product application

It is especially suitable for the crushing and recycling of various rigid plastics, and the effect is better. The optimized design of the tool holder is divided into blade type, claw type and flat blade type. The claw type knife can disperse the force, so that the shear of each knife is increased, especially suitable for thick products, large rubber heads, hard material blocks, etc., which effectively improves the cutting force of the tool and reduces the tool wear. Equipped with electronic control safety design and multiple safety protection devices to ensure safe operation.

It is suitable for smashing large pieces of defective products of various materials and shapes, and can be smashed and recycled in a centralized manner.

本The series of models have a variety of flexible tool materials and structures for different crushing materials, and have a wide range of applications: including injection molding, blow molding or centralized crushing of waste.

二、product referral

The motor is equipped with an overload protection device, a power supply chain protection system, and a cleaning tool protection device. The operation and cleaning are absolutely safe; ensuring the safety of maintenance personnel.

The tool material adopts imported high-quality SKD-11 (optional). Durable.

The standard configuration of screen mesh is 10HP & below is 8MM, the standard configuration is 15HP & above is 10MM, other specifications can be customized.

Unique design, minimum horsepower, but good efficiency, and equipped with double-layer noise reduction equipment, low noise.

When crushing transparent materials and white materials, the feeding hopper and screen should be made of stainless steel, so as not to peel off the paint during crushing, pollute the raw materials and affect the color.

Easy-to-remove design: the feeding hopper, the scraping knife and the filter can be disassembled and easy to clean.

三、Product Features

1. Double-layer feeding hopper, filled with sound insulation material, effectively reducing working noise;

2. The crushing chamber is fully polished and ground, and the thickened steel plate is processed as a whole after welding, with good precision;

3. The tool holder is processed by wire cutting to ensure the accuracy, it is perfectly matched with the central axis, and the assembly is clean and neat

4. The central axis and the tool rest are assembled and formed by hydraulic pressure, without any solder joints and no hidden materials, which is conducive to cleaning, and at the same time avoids the deformation of the central axis due to welding.

5. The top knife block of the blade-type knife holder is cut from the same thick steel plate as the knife holder, which is beautiful and elegant, will not shift or fall off over the years, and avoid welding slag accumulation at the same time.

6. The claw knife type adopts a symmetrical stepped arrangement, which disperses the impact load and makes the crushing of large-sized blocks more labor-saving. Each knife can be rotated 180 degrees for secondary use, reducing the number of sharpening.

7. The tool is made of imported alloy steel. According to the characteristics of different materials, SKD-11 or SKH2 inlaid steel is selected, and the perfect material ensures excellent quality

8. Above SMD-150, it is equipped with a cooling water device for the crushing chamber, which can effectively reduce the working temperature of the crushing chamber and avoid material agglomeration.

Optional equipment:

1. For fibrous materials, the parts in contact with the raw materials, such as the crushing chamber, are all surface-treated

2. Full material alarm device, when the receiving box is full, the machine will stop, and an alarm light or buzzer will sound

3. Feeding conveyor belt, large-scale pulverizers are difficult to feed materials, using conveyor belts can easily send materials into the pulverizing chamber

4. Recycling and storage system, which automatically transports the crushed materials to the storage bucket, which is convenient for subsequent bagging and packaging

5. The dust separation system can separate the dust in the pulverized material from the granular material, the particles are directly recycled, and the dust is collected in the filter bag

6. Screens, screens with special apertures can be customized

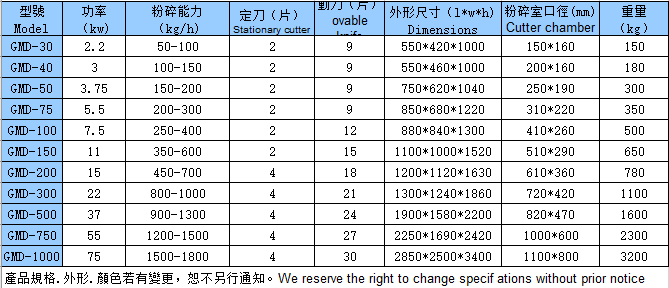

四、technical parameter

刀架结构Tool holder structure