。

切胶机 | 橡胶切胶机 | 橡胶切条机

Rubber Cutting Machine | Rubber Cutting Machine | Rubber Cutting Machine

一、Product application

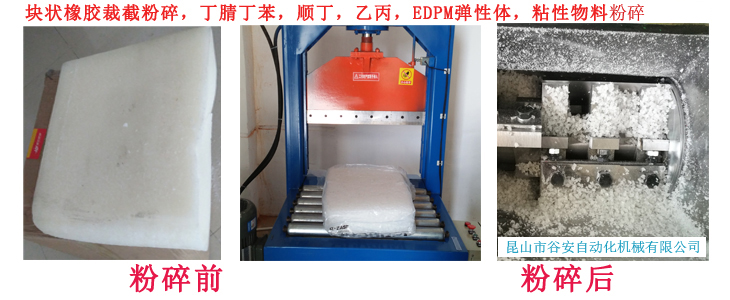

The rubber cutting machine, rubber cutting machine and rubber cutting machine produced by Gu'an Machinery are one of the important mechanical equipments in the rubber crushing production line, which are mainly used for cutting and cutting rubber. Its function is to cut rubber or synthetic rubber blocks (packs) into smaller blocks that are easy to process. It is convenient for crushing or plasticizing process of rubber mixer.

二、Product features

The slitting machine is one of the types of dangerous operation equipment, so Gu'an's safety design ranks first, with special guardrails and electrical interlocking safety protection. Secondly, the slitting machine is mainly used for rubber Before the crushing process, it has a great relationship with the size and configuration of the crusher. The slitter and the crusher can be selected and configured to achieve cost-effective optimization. For customers with low output requirements or the price budget of the crusher exceeds the standard, That is the gospel of shopping. According to the requirements of cutting output, shape and material characteristics, different functional models of cutting machines can also be customized, and the materials of the cutting blades are also different. For details, please contact the sales staff of Gu'an Machinery.

三、main feature:

1. The cutter enters and exits the material port, and the protective net is installed.

2. With manual and automatic switching

3. Nylon or soft lead pads are installed on the base under the glue cutter to protect the blade of the glue cutter

4. The upper and lower limit switches are installed on the frame to change the movement direction of the rubber cutter and also protect the piston cylinder cover.

5. The feeding table adopts the rolling method, and the feeding is light

6. The overflow valve in the hydraulic system, when the resistance is too large and the operation is abnormal, the overflow valve automatically unloads

7. The hydraulic system of the new machine should be cleaned after 200 hours of use, and the new oil should be replaced

8. The tool is easy to disassemble and assemble, and can be used for grinding and repairing

Rubber Cutting Machine | Rubber Cutting Machine | Rubber Cutting Machine

四、technical parameter

五、working principle

The motor drives the oil pump through the coupling. When the "down" button is pressed, the coil on the right side of the solenoid valve is energized, and the hydraulic oil enters the upper chamber of the working cylinder through the reversing valve. At this time, the rubber cutter is driven by the cylinder piston rod. The rails on the rack are lowered to cut glue. The frame is equipped with upper and lower limit switches. When the rubber cutting action is completed, touch the lower limit switch to make the coil on the left side of the solenoid valve energized, change the direction of the hydraulic oil, and make the rubber cutting knife rise. When the rubber cutting knife rises and touches the upper limit switch, the pressure oil returns to the oil tank through the reversing valve, and the rubber cutting knife stops moving.

六、Photo exhibition

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support