。

Zhenjiang Blister Online Crusher | Cup Making Online Crusher Model

一、Product application

吸塑在线粉碎机,制杯在线粉碎机Blister on-line shredder, cup-making on-line shredder is used to manufacture environmentally friendly plastic packaging boxes, plates and fruit packaging boxes and other packaging machinery.

二、Use of the product

Suitable for crushed products: PP, PET, PS, PVC, PLA, bio-based materials and other disposable plastic products, food packaging, plastic blister trays, plastic blister packaging.

三、Product features:

This series is designed for plate, sheet or edge material, and there are many different feeding methods for selection. With the corresponding size of the crushing cavity size and knife type, the material can be simply crushed. This series can be equipped with a traction device, which can automatically pull the infinitely long edge material, sheet material and plate material into the crusher for crushing without manual feeding. It is suitable for thermoforming, paper cups, environmentally friendly lunch boxes, blister packaging and other forming machines.

1. The material is thin and light, and the cutter is not easy to cut the material, which has a great impact on the machining accuracy of the machine, and low-precision equipment cannot fully meet the requirements

2. The length is infinitely extended. For crushing, the feeding design is the key.

3. The speed is different, its speed changes with the change of the host, and the design method of the traction changes accordingly

4. The width is different. For the crusher cavity, this is one of the important parameters for selecting the size of the machine.

5. The thickness varies, any design is limited to a certain value, and the thinnest and thickest are all within this range.

Therefore, it is impossible for one machine to meet all material crushing requirements. Please tell your crushing requirements, and we will help you select models together. I believe we will be able to choose a more suitable and satisfactory model.

Blister online pulverizer, cup making online pulverizer

四、Product Features

4.1 Traction part: [multiple ways of unique design]

The traction spindle is precision machined with high-strength seamless steel pipe, and then plated with hard chrome, which is beautiful, never rusted, durable and environmentally friendly.

The body is made of national standard steel, which is beautiful and durable.

The power part adopts the gear reduction motor of the famous brand manufacturer, and the new integrated design is convenient, light, durable, and equipped with the frequency converter of the famous brand manufacturer, which can be used synchronously with the host, the speed can meet the needs of different customers, and the quality is stable.

4.2 Feeding fan part: [multiple structures, easy to collect]

The base of the feeding fan is welded by the national standard angle iron. At the same time, the motor from famous brand manufacturers is adopted, which is of stable quality and durable.

The fan shell and blades are made of stainless steel, which is beautiful, never rusted, environmentally friendly and hygienic, and durable.

The unique fan blade design increases the wind pressure, and has strong material conveying ability and stable operation.

4.3 Crusher part: [a variety of tool holders, optional special materials]

The knives are made of special steel from famous brand manufacturers, with high hardness, good toughness, strong wear resistance, especially strong and durable, easy to crush various soft and hard materials, and strong crushing ability.

The body is made of high-quality steel plate welded and processed, which is strong and durable, and will never burst.

The frame is welded by national standard channel steel, and is equipped with screw fixing device to maintain the stability of the machine.

The tool holder adopts a hollow structure design, which is stable in operation, small in wind resistance, fast in heat dissipation, and durable.

The bearing adopts the bearing of the famous brand manufacturer, which is stable and durable. The flywheel and pulley are finely cast and precisely machined, so they are sturdy and durable.

The thickness of the pulverized raw material ranges from 0.5 to 3 mm. [If other thickness materials, please specify when ordering].

Simple operation, reliable performance, low noise and high quality.

Adopt synchronous belt drive mode, mature technology and stable operation.

Blister online pulverizer, cup making online pulverizer

Thank you very much for viewing Gu'an's online blister pulverizer, cup-making online pulverizer, Gu'an's blister online pulverizer, and cup-making online pulverizer are basically produced according to customer orders, each equipment is for It is carefully tailored by the customer, so there are many types and models of equipment produced. The same type of machine will be designed according to the performance and process requirements of the material to be crushed by the customer, and the structure configuration is also different. Therefore, the technical labor and materials used The cost is also different. Naturally, the delivery time will be longer than that of ordinary spot machines, and the performance and price cannot be compared with ordinary machines. If you have questions about crushing convenience, please click to contact you.

Reasons to use a blister in-line pulverizer and a cup-making in-line pulverizer

This model is suitable for on-line crushing of runner materials in the manufacture of wide-faced environmentally friendly drinking cups. In the production process of the cup making machine, usually when the finished product process is to be packaged, there will be reticulated wide-faced nozzle material, which is collected by the winder according to the traditional method, and then manually transported away for centralized crushing. It will consume labor, produce pollution and reduce product quality. This model is also suitable for single use of coil materials. When used as an edgeless in-line edge feeder pulverizer, many coil materials collected are too heavy to be crushed. Gu'an Machinery can design customized brackets to easily eliminate your troubles. , Turn waste into treasure, clear out space, and beautify the workshop.

The benefits of using a blister in-line pulverizer and cup-making online pulverizer

In view of the above situation, our company has developed an automatic operation system integrating crushing, conveying and storing materials. During this process, the crushed materials are all carried out in a fully enclosed state, which avoids pollution, saves labor, and achieves the purpose of environmental protection. The production process is improved, the production environment is improved, and the effect is to change the traditional backward productivity. As the labor becomes more and more tense, this model is more and more popular with customers!

1. Original inlaid steel tool, the edge hardness is 58-62 degrees, excellent cutting performance, strong wear resistance; [tool material can be customized]

2. There is no welding point on the knife shaft, no deformation, high concentricity, impact resistance and wear resistance;

3. The tool holder adopts a hollow structure design, which is stable in operation, small in wind resistance, and durable; [The tool holder structure is optional]

4. The cup-making online pulverizer adopts synchronous transmission mode, with mature technology and stable operation;

5. The thickness of crushed raw materials ranges from 0.5-3mm; [other specifications can be customized]

6. Movable screen, easy to replace and clean. 【Aperture of screen mesh can be customized】

In response to the above problems, Gu'an company independently developed and designed an online plastic blister pulverizer and an online cup-making pulverizer. This model can automatically pull the mesh sheet waste generated after cup making into the pulverizer at the same time as the waste is discharged. , In this process, the material is not hygroscopic or polluted, and the crushed fragments can be immediately transported to the storage tank by the fan for recycling. And because the edge material is not wound, it is crushed as a thinner sheet, and the crusher Less power, saving more than 30% of electric energy

六、picture display

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

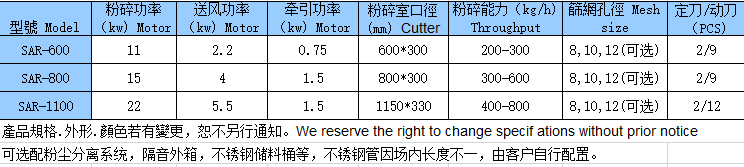

Product selection

technical support