。

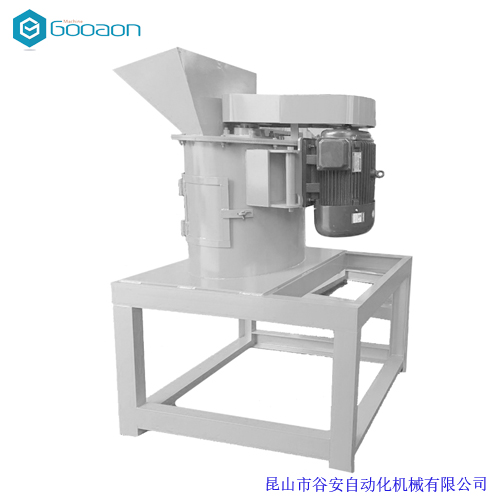

Wet material crusher | Fermentation material crusher | High humidity material crusher

Scope of application:

It is widely used in dry block crushing of organic fermented substances, grass peat charcoal, lees cakes, organic fertilizers, industrial organic waste, and sludge organic matter;

Dry and wet fermentation of livestock and poultry manure; crushing of municipal solid waste, and has a good grinding effect on glass, broken ceramics, bricks, etc.

Wet material crushing principle:

The two-stage rotor is used for upper and lower crushing. The material is crushed into fine particles by the upper-stage rotor crusher, and then transported to the lower-stage rotor.

Continue to pulverize into fine powder to achieve the best effect of material powder and hammer powder, and finally discharge directly from the discharge port.

Product features:

1. The vertical crushing chamber is equipped with an observation window, which makes it easier to understand the crushing status.

2. Special tool material: it has three times the service life of similar products.

3. Easy to replace the tool: easy to replace the wearing parts, it can be completed in 10 minutes.

4. Tool holder structure: Tool holder design, different combinations of multi-layer tools, better upgrade effect.

5. The particle size of the material can be controlled by adjusting the gap between the hammer and the liner.

6. No screen design, especially for materials with high moisture content, it is more adaptable, not easy to be blocked, and the material is unloaded smoothly.

7. High alloy wear-resistant hammer head is used, which is particularly strong and wear-resistant, which increases the service life of the hammer.

8. Using two-way adjustment technology, if the hammer is worn out, it can continue to be used by moving the position of the hammer.

Wet materials are prone to the following problems during the crushing process:

1. The material is too wet, it will stick to the knife, and the material will not be blocked.

2. The wet material agglomerates and blocks the knife and cannot be separated and crushed.

3. The material is heated up by repeated friction in the crushing chamber

4. In case of heat, it will clump together and cannot be used.

5. Glue on the cutter and screen.

Wet material crusher | Fermentation material crusher | High humidity material crusher

Product parameters

Tool holder structure diagram

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support