。

Plastic dehumidifier | Rotary dehumidifier | Honeycomb dehumidifier is mainly used to process engineering plastic raw materials with strong hygroscopicity for dehumidification. The dew point of the honeycomb runner can reach below -50℃ under ideal conditions. There are 12 models in this series, and the drying air volume can reach 3000M3/HR

Plastic Dehumidifier | Rotary Dehumidifier | Honeycomb Dehumidifier

一、product referral

新型New plastic dehumidifier | Rotary dehumidifier | Honeycomb dehumidifier is widely used in drying of various plastics, especially engineering plastics with strong hygroscopicity. Under ideal conditions, the dew point can reach below -40℃. There are more than 10 types of products in this series, and the drying air volume can reach 4000m3/h.广泛适用于各种塑料的干燥,特别是吸湿性较强的工程塑料。在理想状态下露点可达-40℃以下。该系列产品共有10多种机型,干燥风量可达到4000m3/h.

二、Product features

◆ Adopting a new type of honeycomb runner and environmental protection and energy-saving design, the dehumidification performance is further improved.

◆ The runner uses molecular sieve as the moisture-absorbing base material, which overcomes the shortcomings of traditional honeycomb formation, which is difficult to form, high in cost, and easy to wear.

◆ Low cost of runner replacement, durable and long service life.

◆ The runner adopts a unique area interval and heat insulation design, which saves about 30% energy than other dehumidifiers;

◆ Dry air can reach low dew point below -40℃.

◆ Adopt P.I.D temperature control system, which can control the regeneration temperature completely.

◆ A return air filter is installed inside to ensure that the runner is not polluted by dust.

◆ Optional PLC control with LCD touch-sensitive human-machine interface, centralized and convenient operation, can control the automatic operation of the whole machine.

◆ Optional dew point detection device.

◆ There are heat-resistant air ducts, cyclone dust collectors and oil filters available for purchase.

三、Features:

1.1. The honeycomb type washable ceramic runner is adopted, which will not produce dust after long-term operation, which can maintain the cleanliness of raw materials, avoid pollution, and ensure product quality.

2. During continuous load operation, the dew point can be maintained at -32~-40℃. In the case of chilled water, it can even reach below -40°C, and the dew point curve remains stable without ups and downs.

3. The intelligent microcomputer LED panel can automatically display various operating states, with simple operation and perfect functions.

4. Embedded drying air and regeneration air filters are easy to clean.

5. The cooler adopts stainless steel easy-to-disassemble design, which is more convenient to clean when drying oily plastics.

6. It has protection devices such as under-reverse phase, abnormal operation, motor overload and regeneration over-temperature.

四、How to choose a dehumidifier model?

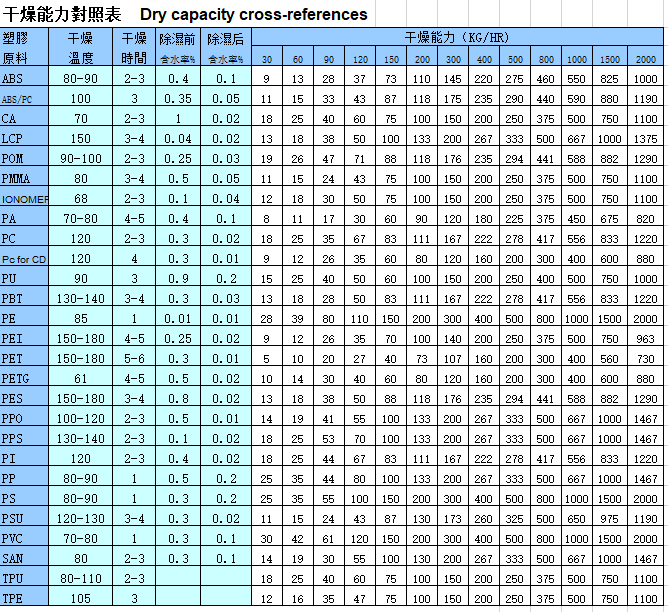

Step 1: Determine the injection volume per hour of the molding machine and the name of the raw material Step 1: It has been determined that the injection volume per hour of the molding machine is 50KG and the name of the raw material is ABS

The second step: injection volume X1.2 = drying volume Second step: injection volume 50KGX1.2 = drying capacity 60KG

Step 3: Select the drying capacity corresponding to the name of the raw material Step 3: The drying capacity corresponding to the ABS raw material is 73KG (generally slightly larger than the theoretical value)

Step 4: The model of the dehumidifier corresponding to the drying capacity is the correct model. Step 4: The model of the dehumidifier corresponding to 73KG is GRD-150, which is the correct model.

Plastic Dehumidifier | Rotary Dehumidifier | Honeycomb Dehumidifier

五、Product parameters

General comparison table for drying capacity of plastics

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support