。

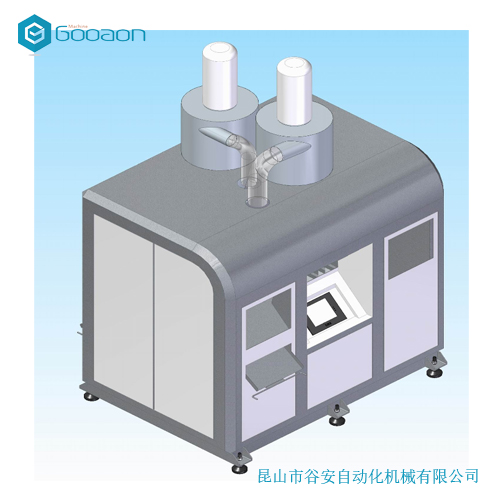

Copper rice machine | Copper plastic separator | Cable crusher

1、The main purpose:

The unit is suitable for all kinds of wire and cable, household appliance wire, communication wire, computer wire and other waste wires, large and small wires that are not suitable for stripping machines.

It can be shredded at the same time without sorting, and realize the dry separation and recycling of various waste wire metals and plastics. With large production capacity, low power consumption, sorting

High rate, one feeding, multi-machine cooperation (crushing, conveying feeding, vacuuming and dry separation), fully automatic intelligent control, only one person is required

It can be produced after feeding, and advanced dust collection device. It not only improves the quality of recycled copper, but also recycles plastics and solves the problem of pollution of the environment.

2、working principle:

Under the action of wind, the two materials with different densities are deflected by the amplitude movement on the screen surface with a certain angle, so that the copper wire with high density will move forward against the screen facing the copper outlet, and the plastic skin with low density will float on the copper wire. The top of the wire flows to the skin outlet, so as to achieve the purpose of separating copper and plastic. The clean rate of separation is proportional to the diameter of a single copper wire. The larger the diameter of a single copper wire is, the cleaner the separation of the plastic will be, and the greater the output per unit time will be. the worse.

3、Scope of application:

All kinds of wire and cable, household appliance wire, communication wire, computer wire and other waste wires that are not suitable for processing by stripping machines.

4.design principle

The copper-plastic separation system produced by Gu'an Company adopts the air-selected copper-plastic separation technology. Safe use of vibration and wind separation to achieve separation effect, to avoid secondary pollution to the environment caused by traditional wet separation.

As long as the waste wire is put into the shredder, the whole system will automatically carry out all the processes. Technically, thin copper wires with a wire diameter of 0.05mm-2.0mm can be separated, and the separation cleanliness is as high as 99%. There are obvious differences compared with ordinary copper wire separators.

This equipment can accurately separate copper and PVC sheaths for different waste cables and wires. And the failure rate is extremely low, and the output of the machine is stable. The hourly workload can reach 100-700kg.

5.Advantages of copper plastic separator

1. All kinds of wires of different sizes do not need to be sorted, they can be put into the equipment at the same time, and clean copper and plastic can be automatically separated after crushing;

2. The whole set of equipment adopts a platform combination design. After receiving the machine, the customer only needs to connect the power to use it, and there is no need to assemble and debug again;

3. The outer box of the whole machine is humanized, and each process is closed to prevent dust from entering the working environment;

4. PLC control, uniform feeding, intelligent operation, can automatically adjust the feeding frequency of the front end according to the workload of the back end, without making the system is shut down due to overload, the operation is simple, saving time and effort;

5. Wide range of application, wire and cable with wire diameter of 0.5-30mm can be used, and the length is not limited;

6. The crushing tool is made of alloy steel with high hardness, which is wear-resistant and impact-resistant and has a long service life;

7. The crushing system is designed with 4 sets of moving knives and 3 sets of fixed knives, improving the efficiency by more than 30%;

8. The same production capacity, lower power consumption;

9. The whole system is sealed and collected by multi-stage dust filtration, which does not pollute the environment

Copper rice machine | Copper plastic separator | Cable crusher

6、Product parameters

Business hotline: Miss Liu 13776319563

Technical support: Gu Gong 18913224469

e-mail address:gooaon@163.com

Ali Wangpu:https://www.gooaon.com.cn

Address: No. 56, Gangpu East Road, Zhangpu Town, Kunshan City, Suzhou, Jiangsu Province

Product selection

technical support